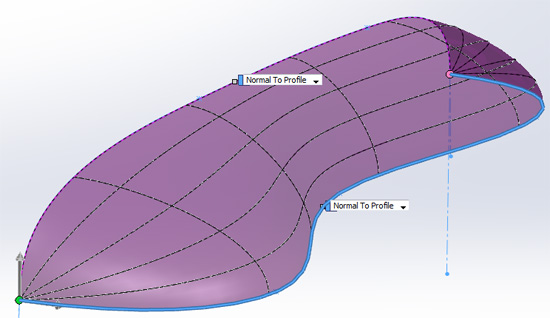

The surface above represents a degenerate surface, which “occurs when one or more sides of the parametric quadrilateral surface used for meshing collapse to a singularity.” Source: Ansys Workbench

In SolidWorks this happens when trying to apply a boundary surface to a boundary that is not four sided. The result is that SolidWorks forces the curvature into the corner of a boundary, which creates a singularity at the corner. This may seem trivial, but when you go to thicken the surface or add fillets, you’ll find that more often then not the feature will fail or be produced incorrectly.

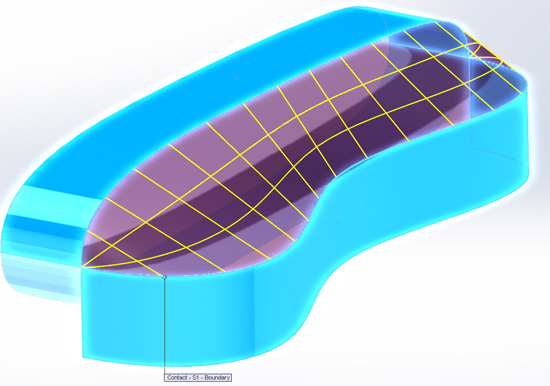

This is where the fill surface tool comes in. The fill tool overbuilds a surface, as shown in the third picture, as a four sided surface, then trims it back to match the boundary. When you go to work with the geometry created using the fill surface tool, you should have no issues when moving to solid geometry.

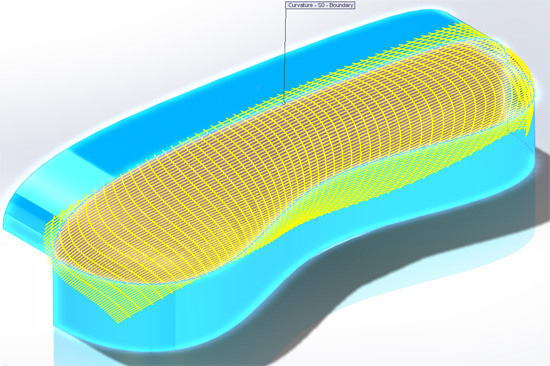

There are exceptions though. For example, if you have the optimize surface option of the fill surface selected, the fill tool will generally try to create a boundary surface. The picture above shows the result. You get the same singularities that are accompanied by issues when working with the resultant solid body.

This is one reason why you’ll usually want to uncheck the optimize surface option. If you want a boundary surface, use a boundary surface otherwise use the fill surface with that option unchecked. A more detailed tutorial is included, so that you can see how both of these tools work: